It’s no secret that the buzz around every major industry right now is with the supply chain crisis and its continuing challenges, not the least of which is headwind inflationary pressures. A big item on the agenda at the CropLife America Conference in September 2021, supply chain issues – particularly escalating costs and shipment delays – has forced many businesses to come up with a strategy and solutions to keep customers happy and keep business profitable. With no immediate relief in sight, it’s time to admit we’ve entered an inflationary period that will impact all of agriculture. How businesses are able to adapt and respond will affect both the individual company and the industry as a whole.

Rapidly Escalating Costs

Nearly every aspect of the supply chain is experiencing record highs—particularly freight costs driven by lack of labor availability, higher wages and higher fuel costs. This has skyrocketed the cost of inbound raw materials and outbound finished products.

Logistics and Shipping Delays

Escalating logistics costs, shipping delays and bottlenecks have become a nightmare situation for many. Our clients are experiencing delays in acquiring their raw materials and in providing those materials to us for pilot plant scale-up and manufacturing.

How Can We Mitigate (or Solve) Supply Chain Challenges?

Every good businessperson will tell you that new challenges simply force honesty and discipline back into a business’ operations. It forces “good behavior” in terms of better planning and better execution. It forces companies to strive for a standard of excellence, as they should always be doing.

By breaking apart each step in your operations processes, you can identify weak links and shore them up. The less chinks in the armor, the less room for disruption.

Related: Factors to Consider When Formulating an Agricultural Chemical Product

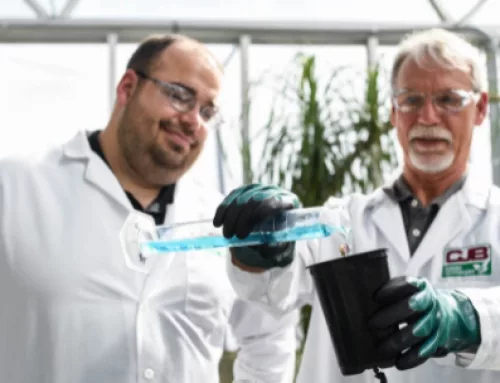

What Solutions are Being Implemented by CJB Applied Technologies?

“We’re starting off by increasing customer communications,” says Jim Loar of CJB Applied Technologies.

“We’re starting off by increasing customer communications,” says Jim Loar of CJB Applied Technologies.

“By keeping in frequent contact with our customers throughout the planning and material acquisition process, we can stay abreast of possible delays and do everything we can to adapt by either speeding up or delaying their scheduled project start dates.”

Jim Loar, CJB Applied Technologies

If the client is delayed in receiving raw materials, then there is a domino effect, pushing back product development and pilot plant production. Many of these services are perishable, and a one day delay equals a financial loss. If we understand client challenges, we can do our best to accommodate those challenges so that neither party has to experience productivity or monetary loss.

In order to partially compensate for a loss due to scheduling delay, CJB Applied Technologies is absorbing 50% of the cost of the loss per day, while the customer is asked to shoulder the remaining 50% of the cost.

“We can’t bear 100% of the cost; it’s just too much. But we can help lighten that burden somewhat and work with customers to improve planning and communications so we can help compensate for material and scheduling delays,” Jim adds.

He continues, “We’ve done our best to cut costs in as many areas as possible to prevent having to pass inflationary pressures on to our customers. While we have had to raise costs, like everyone, we’ve been able to keep that to a bare minimum by compensating in other areas.”

We’re smack dab in the middle of the height of this inflationary period, and it’s sink or swim for those that haven’t yet sunk.

By implementing better processes and holding ourselves accountable to a standard of excellence, we can minimize the impact of the agricultural supply chain crisis challenges and still provide our customers what they need when they need it.

Interested in Contract Development with CJB Applied Technologies? Our pilot plant allows you to manufacture small batches before going to full commercial scale. Pilot plant production helps de-risk the product development process.

Learn more about Our Process