If you have a product formulation idea you want to execute, you may be looking for a way to get it developed and then on to a toll manufacturer.

A contract development and manufacturing organization (CDMO) can be the bridge that takes your product from an idea to formulation development in a lab to production in a plant, and then to commercialization.

Here is why you may need to work with a CDMO like CJB Applied Technologies first to make your toll manufacturing process more successful.

What Does a Toll Manufacturer Do?

A toll manufacturer is a company with specialized equipment that processes raw materials or semifinished goods for another entity and turns them into a finished product for a fee. Toll agreements usually include product processing, labeling, and packaging.

The benefits of working with a toll manufacturer may include capital and labor efficiency as well as regulatory, safety, and health compliance. You may be able to respond to customer demands faster and eliminate the need for overhead investments. You also can maintain control over the specifications, price, and quality of raw materials.

CJB Applied Technologies has partnered with our sister company, CJB Industries, Inc., a well-known toll manufacturer to ensure a smooth transition from the lab and pilot plant to full-scale production. CJB Industries combines chemical-manufacturing excellence with exceptional customer service. They possess professional expertise, comprehensive capabilities, and world-class facilities.

Why Should I Work with a CDMO First?

If you don’t have the resources available to formulate your chemical idea, or those resources are at capacity, you should consider partnering with a CDMO before the toll manufacturing stage. Or, if you don’t have the technical expertise or proper equipment to self-develop your chemical idea, a CDMO can help.

If you’d rather not worry about safety regulations, human resource issues, and other time-consuming concerns that could slow development, production, and commercialization, you should talk to a CDMO.

Proven Process

At CJB Applied Technologies, we develop your idea into a product from start to finish, communicating with you at every level. Here is our process.

1. Discuss Idea

We have an initial conversation to get a basic understanding of your overall concept to make sure we are the best fit for the project. If your idea is a match with our expertise and equipment, we’ll be able to carry your idea through development, formulation, testing, scale-up, and packaging.

2. Develop NDA

Before discussing any sensitive details, we take the necessary steps to formally protect your idea. We develop a non-disclosure agreement (NDA) in order to respect your rights to protect and own your intellectual property. This is usually done with a mutual NDA, an agreement that protects all parties involved in the discussion.

3. Detail Project

Once the NDA is in place, we dig into the specifics of the project and any special requirements. We work to understand the custom formulation needed. We offer flexibility and expertise to help determine the best paths for development and final production.

4. Quote Price in Phases

We estimate the project in phases so you can alter the plan based on milestone results. We explain how the cost reflects the value; in other words, how the expertise, labor, and materials figure into the price. We will save you money where we can, but not at the expense of the quality level required by your application. The more definition and work you bring to the start of the project, the quicker and less expensive it will be.

5. Agree on Timeline

Many formulation development projects can be completed within a 90-day timeframe—though some may take a year or two. Some smaller (or repeat) projects can be even quicker. We will set up milestones for the projects such as:

- IP search, freedom to operate

- Test batches produced

- Stability and performance tests completed

- Pilot plant volume produced

6. Execute Project

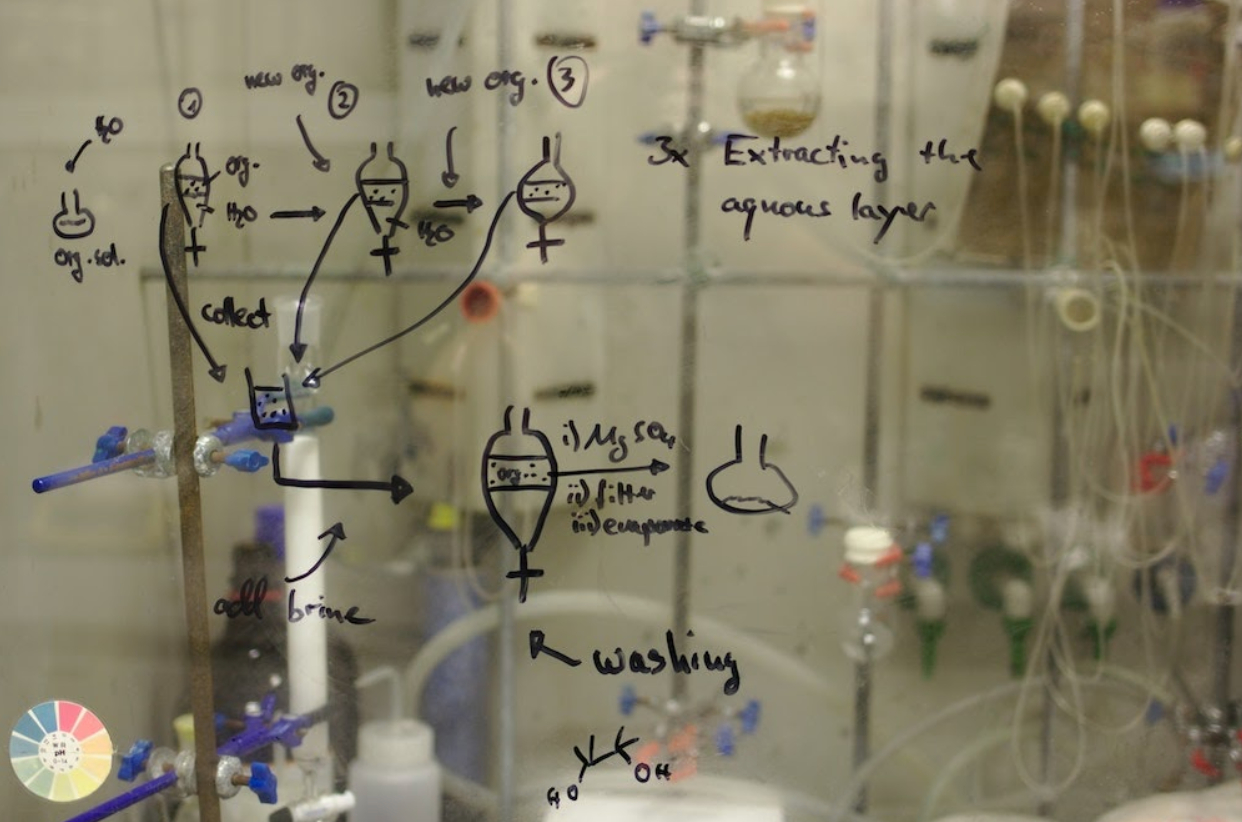

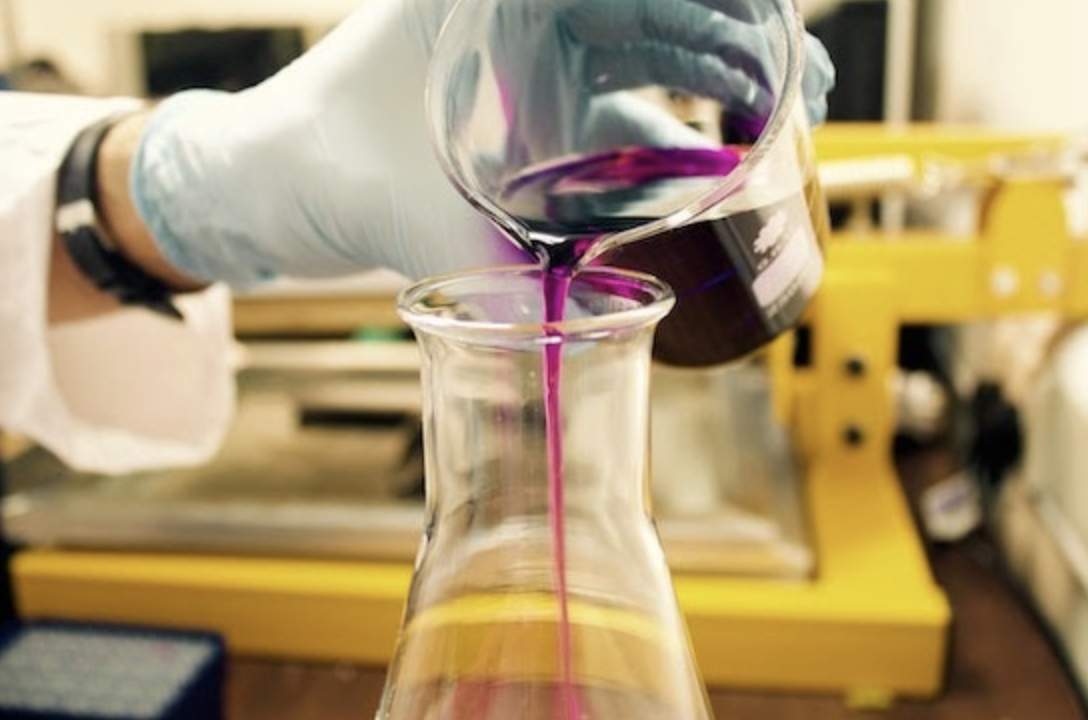

In a typical project, raw materials are gathered and work starts in the formulation laboratory. Lab batches of the product are made, and a top candidate selected. Then, the product moves to the pilot plant for a pilot batch made with similar equipment found at a chemical toll manufacturing facility. This batch will be large enough to be used for registration purposes or in the initial launch of the product.

7. Deliver Results

We review the project with you to make sure the finished result meets (or exceeds) your expectations. We examine the final outcome to confirm the attainment of quality control standards. We help you choose the best chemical toll manufacturing company to go into at-scale production.

What’s It Like to Work with CJB Applied Technologies?

CJB Applied Technologies has a team filled with decades of relevant knowledge and experience in formulation development. We value integrity, quality, consistency, affordability, flexibility, and availability as the core characteristics of our work ethic.

CJB Applied Technologies has strong business processes and adheres to safety and environmental compliance. We also have a long history of meeting objectives and delighting customers.

We have completed projects in many business sectors including:

- Crop protection chemical formulation development

- Turf nursery and ornamental products

- Biological products

- Nutritional products

- Organic products

- Specialty chemicals

How Can I Get Started?

Now you know more about the process of toll manufacturing and how a CDMO like CJB Applied Technologies can help get your product formulation idea to commercialization quickly.

Working with a CDMO before a toll manufacturer may be the most efficient, effective, and affordable path to market. If you’d like to talk with an expert about your life science or industrial chemical formulation development project, contact CJB Applied Technologies today.